Elements of a Twist Drill

Twist drill is a cutting tool comprised of cutting point at tip of a shaft with helical cutting edge. The various elements of twisting drills are described below.

Axis: The center line

Body: It is the main parts of the tool, it extend from the drill shank to the tip of tool.

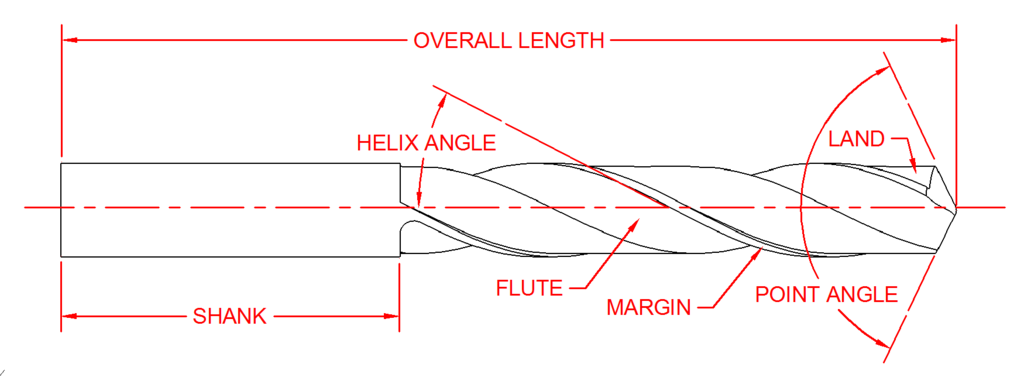

Shank: It is the cylindrical portion of the drill that held in holding device. The shank may be straight or tapered. The parallel shanks are provided in small tool bits. It is held in the machine by chucks. The larger size drills are provided tapered shank called a “Morse Taper”. It carries a tang at the end of the shank to ensure proper grip between the drill bit and drive from the machine.

Tang: It is the flattened end of the tapered shank, which fits into the driving slot in the machine or sleeve. It ensures the positive drive from the drill spindle.

Neck: The portion of reduced diameter in between the body and shank

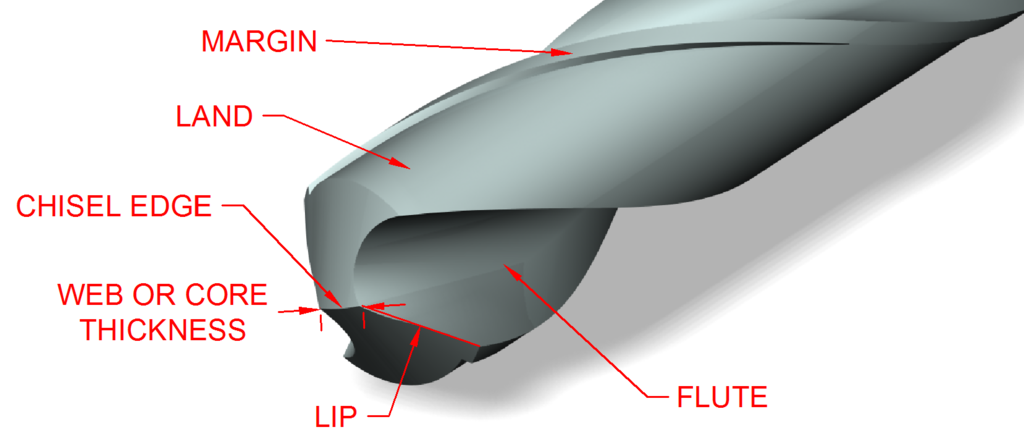

Margin: This narrow extension through the entire body provides clearance between drill and work material. A double margin drill bit have two margin instead of one.

Dead center or chisel edge: It is the point where two cutting edge meets at the extreme tip. It should always be lie in the axis of twist drill.

Flutes: It is the grooves in twist drill, which provides lip or cutting edge.

Flank: surface of drill, which extends behind the lip to the flute.

Lip: It is the cutting edge formed at the intersection of flank and flute.

Rake Angle/Helix Angle

It is the angle of the flute in relation to the work surface. The value of rake angle varies between 18° to 45°; its typical value is 30°.

The rake angle governs the tightness with which chip curls and hence the amount of space occupied by the chip. The higher rake angle cause tightly rolled chip while the small rake angle tends to chip curl into more loosely rolled helix. Large rake angle causes excessive vibration and chatter of drill.

Lip Clearance Angle

It is the angle formed by the flank and a plane perpendicular to the axis. Lip clearance is the relief given to the cutting edges that allow drill to enter into the workpiece without any hindrance. In general purpose drills, the clearance angle behind the cutting edge is 12°. Too much clearance angle cause the breaking of the lip of drill due to insufficient support. Clearance angle should be kept minimum in order to provide enough strength and rigidity to cutting edge. Too little clearance results drills having little or no cutting edge.

Cutting Angle/ Point Angle

The cutting angle is the angle between two lips when it is projected on a plane parallel to the axis. Simply it is the angle between the lips in the side view of a twist drill. Normal of value of Point angle is 118°. Both cutting edges are sharpened at the same angle, so each makes angle of 59° to the center axis.

Chisel Edge Angle

It is the angle included between the chisel edge and lip of the twist drill when measuring on a plane normal to the axis.