Split Pins

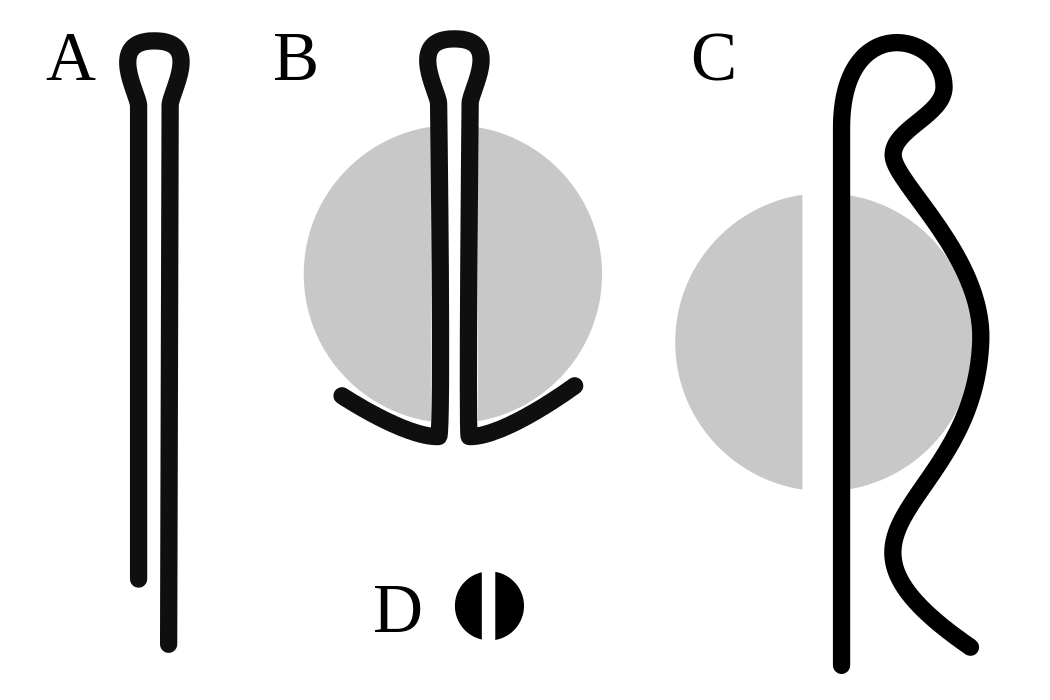

A split pin, also known in the United States as a cotter pin or cotter key, is a metal fastener with two tines that are bent during installation, similar to a staple or rivet. Typically made of thick wire with a half-circular cross section, split pins come in multiple sizes and types.

Taper pin

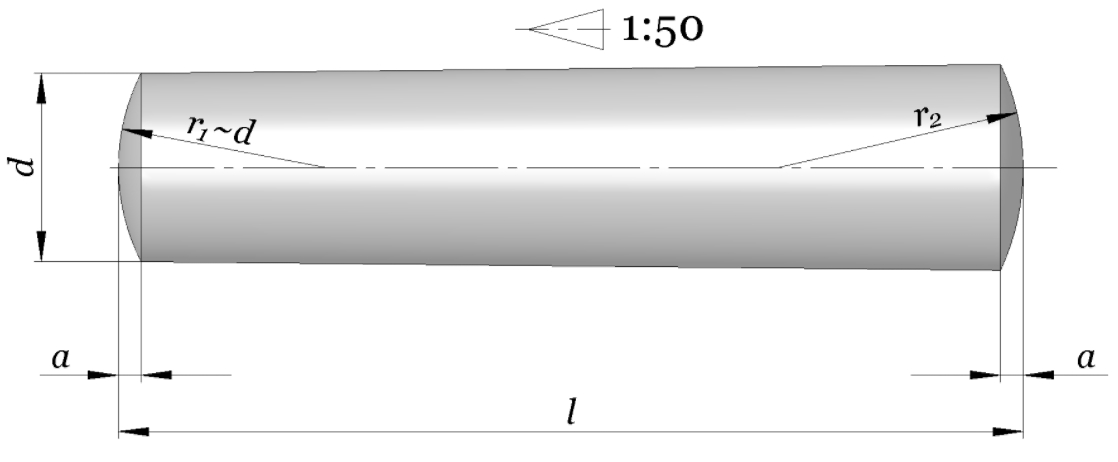

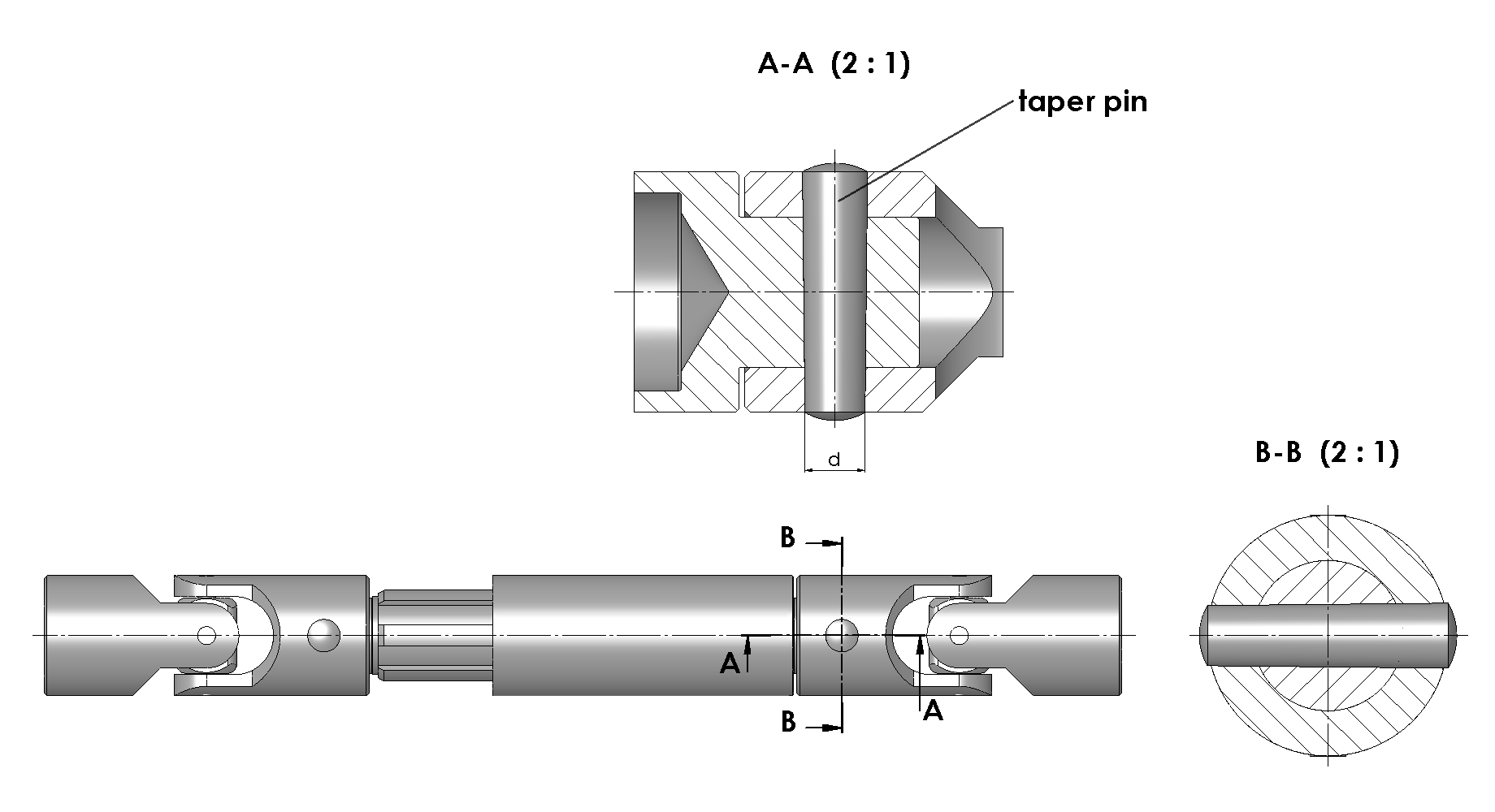

A taper pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Standard inch-sized taper pins have a taper on diameter of 1:48 while metric ones have a taper of 1:50 See Fig 1. A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a 1/4-inch taper over a 1-foot length.

Some taper pins have a male screw thread on the small end that is designed to project through the hole and retain the pin with a washer and a nut. Other pins are threaded on both ends, on the thick end to pull the pin out with the same nut that holds the pin in place.

Taper pin reamers are designed to prepare the hole for taper pins. Metric taper reamers are designated by the small diameter. For example, a 2 mm taper pin reamer has a 1.9 mm small end (2 mm nominal size) and a 2.86 mm large end.

Fig 1 Metric Taper Pin.

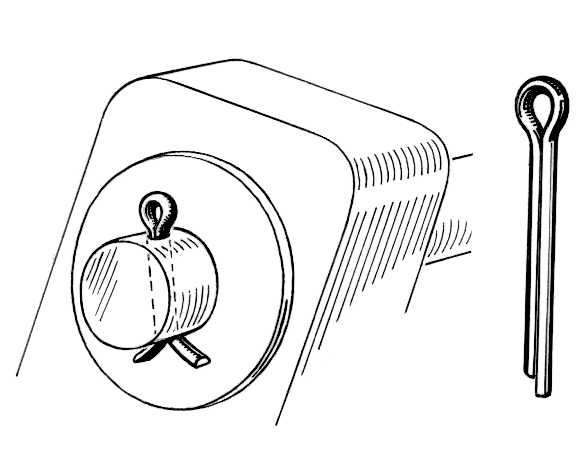

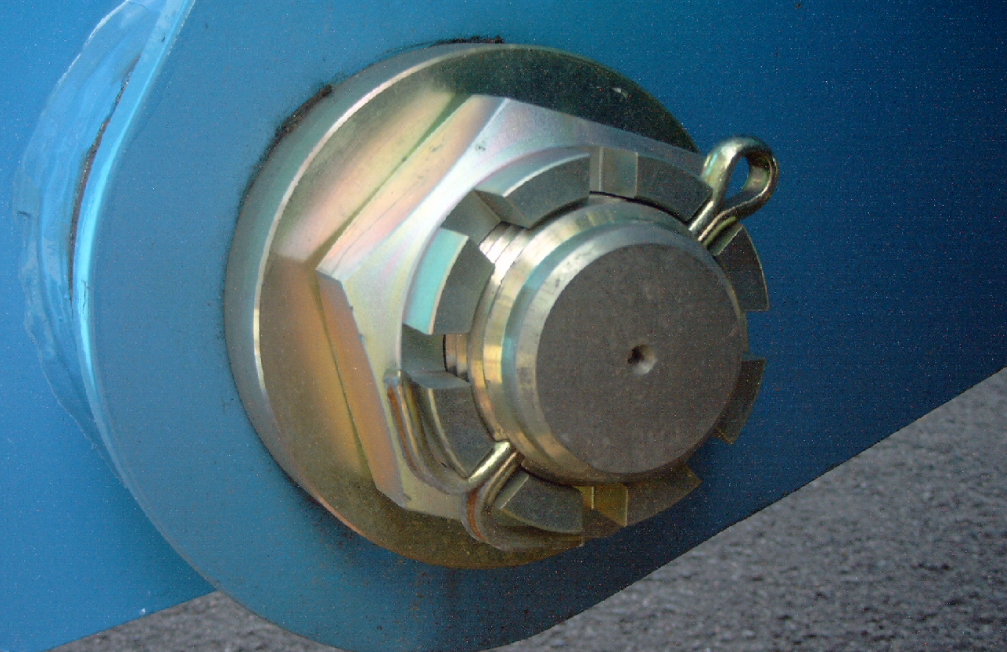

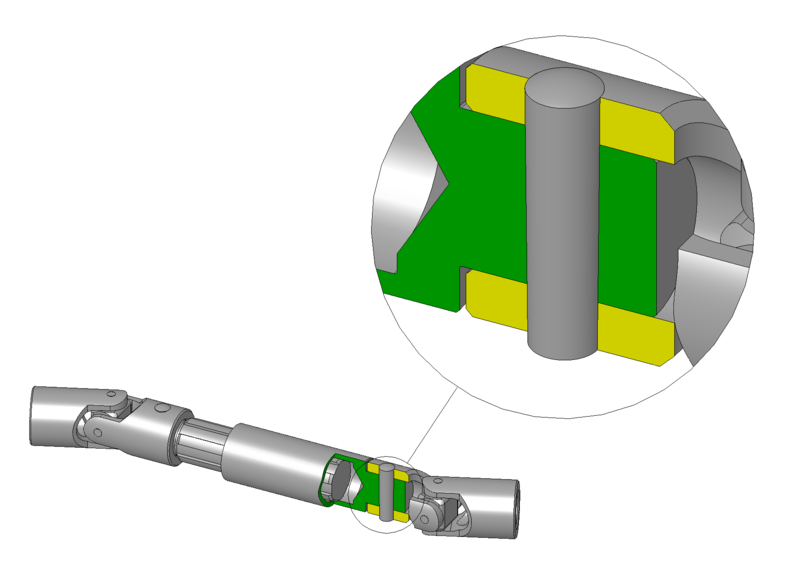

Below is an example of how taper pins are typically used in engineering.

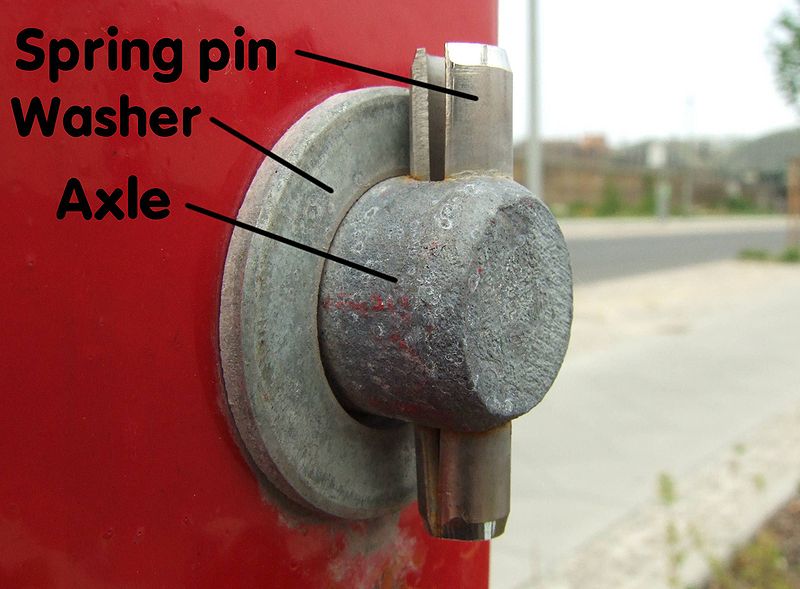

Spring pin

A spring pin (also called Tension pin or Roll pin or Seloc Pin) is a mechanical fastener that secures the position of two or more parts of a machine relative to each other. Spring pins have a body diameter which is larger than the hole diameter, and a chamfer on either one or both ends to facilitate starting the pin into the hole. The spring action of the pin allows it to compress as it assumes the diameter of the hole. The force exerted by the pin against the hole wall retains it in the hole, therefore a spring pin is considered a self retaining fastener. Spring pins are designed for use in double shear applications.

See the video below for non threaded fasteners.