Procedure for making accurate measurement

- open (slide the contact faces) the caliper a little more than the object to be measured

- place the object in the opening

- gently close the instrument until there is contact between the faces and the object

- make sure they are parallel, a small rocking motion if it falls

- make the reading and interpret the measurement

- open the caliper and remove the object

- place both in a suitable location

- repeat the operation to confirm the extent

of course, it is necessary to adapt this procedure for each type of measurement, for example, it is possible to move the caliper measurement before the reading or depth of shoulders or internal measurements for the first step is to open the instrument slightly less than the hole be measured and the sixth step is to close the instrument before removing it from the hole.

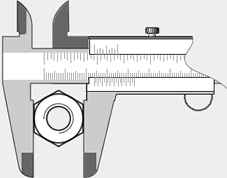

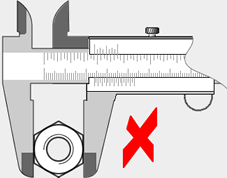

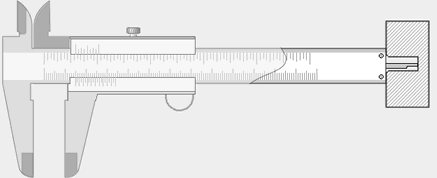

External measurement

Right

Figure 1

External measurement best practices with Vernier Caliper.

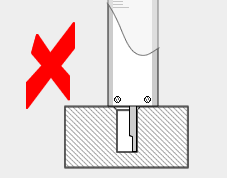

Wrong

Figure 2

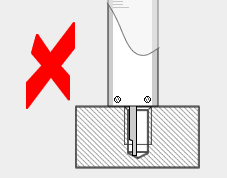

Internal measurement – edge of the blades – the blades can be worn or damaged

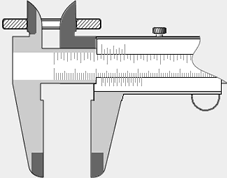

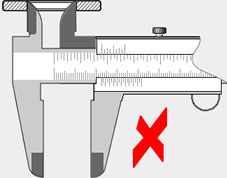

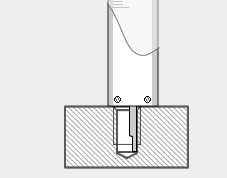

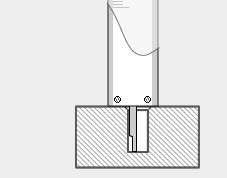

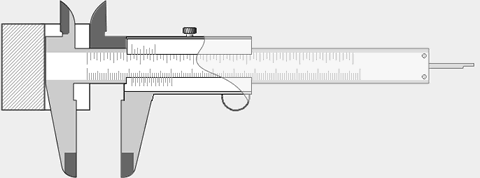

Internal measurement

Right

Figure 3

Good practices internal measurement with universal caliper

Wrong

Figure 4

Internal measurement – edge of the blades – the blades can be worn or damaged

Depth measurement

Instance

Figure 5

Depth measurement with universal caliper

Depth measurement – conical bottom hole

Right

Figure 6

Good practices internal measurement with universal caliper – drill hole

Wrong

Figure 7

End of the blade unable to locate

Depth measurement – blind bottom hole

Right

Figure 8

internal best practice with universal caliper measurement

Wrong

Figure 9

Measurement blind hole – measuring rod against burr

Measurement of shoulders

Right

Figure 10

Shoulder measurement

Some manufacturers caliper added a very interesting feature, which allows the measurement of shoulders. Thus, it can be used to measure lugs with much greater accuracy than that obtained when using the depth rod, Figure 10.